Rubber extrusions Australia are an excellent alternative for tough and long-lasting components. Many reputable industries are manufacturing them for various different industries. These are very important in many manufacturing processes, which is why they are a popular choice for a variety of applications.

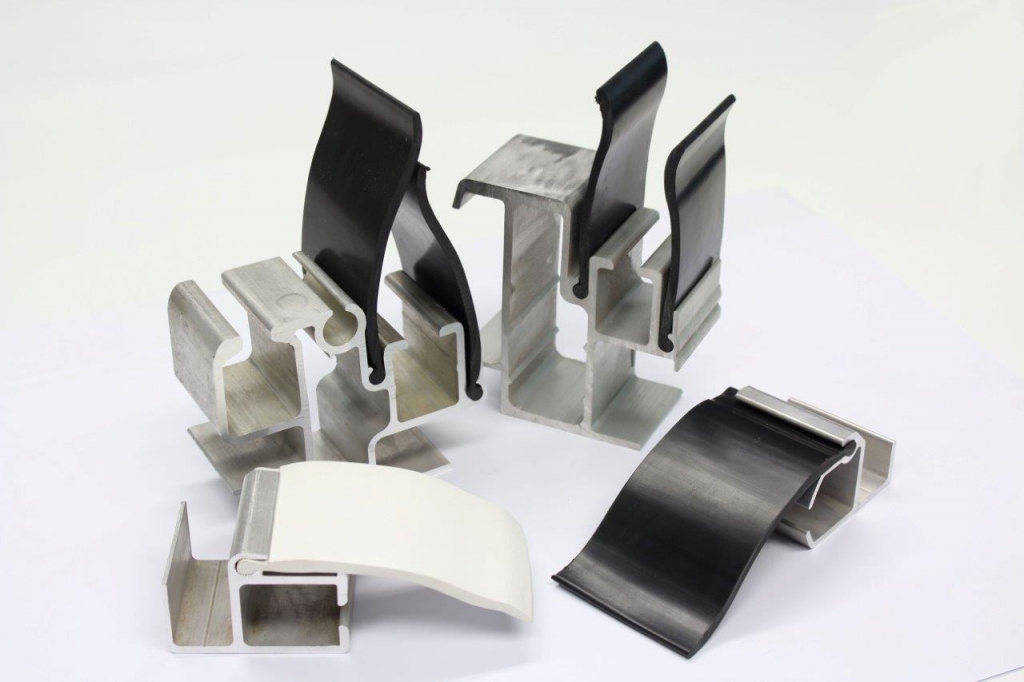

Therefore, rubber extrusion industries develop a wide category of such flexible and durable parts for machines. In this way, the production industry may require rubber t edging, rigid edging, truck pelmet rubber, glazing wedges, bottom door seals, and custom designs, depending on its requirements. Their 3D printing services can help you design new parts.

Benefits of Using Rubber Extrusions in Manufacturing:

Since they are flexible and durable, they are used by a range of businesses to make their machines more functional for further usage. These have great temperature resistance capacity, so they can stay strong in extremely cold and highly heated conditions.

Industries That Use Rubber Extrusions:

Automotive and Marine – The complete development of vehicles is almost impossible without rubber-made items, such as mounts, gaskets, rubber pelmets, seals, and more.

Machinery Manufacturing – No machine can function properly without the support of rubber extrusions. If metal parts are the main components used to construct a machine, then rubber parts are important for the best support.

Construction Industry – They are used as sealing joints between building materials, creating weatherproof seals around windows and doors, and providing vibration damping in buildings and bridges.

Medical – Since they are non-toxic and resistant to sterilisation processes, many medical devices, such as tubes and gaskets for medical equipment, are made using almost the same raw materials.

To conclude, whether you need a small part or various supportive parts for your invention, rubber extrusion manufacturers can assist you to a great extent. However, one should make sure the manufacturer he is dealing with is renowned in the industry.

Find a renowned toolmaking and 3D printing business to consult on your requirements.