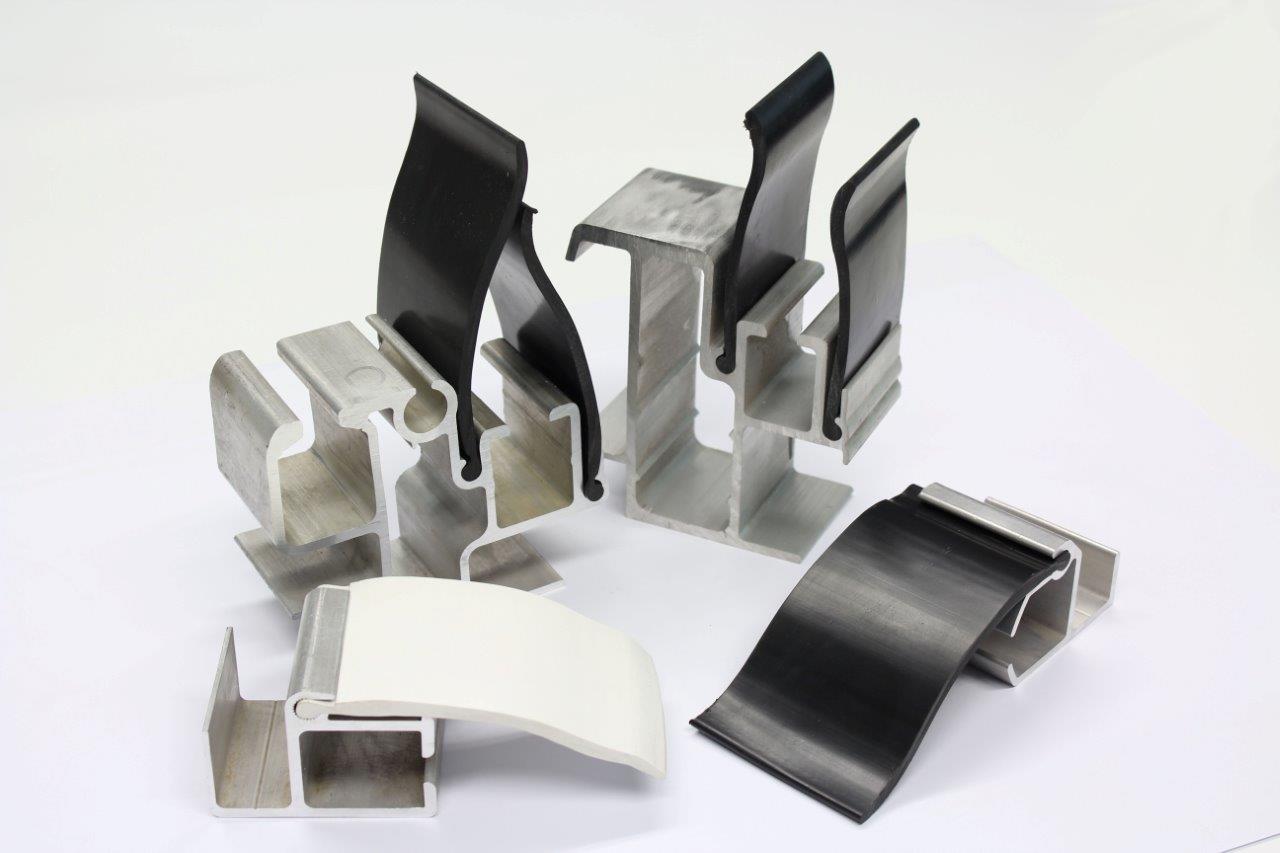

Plastic extrusions, also known as plastic sections or profiles, are widely employed in a variety of industries. It is especially useful for producing plastic parts with uniform wall thicknesses, as well as profiles that are larger and longer than those generated by other methods of manufacture.

Extrusion, in its broadest sense, denotes a pushing out action. Plastic extrusion produces a wide range of items, including films, bags, rubber dock bumper, rods, weather stripping, and deck railing.

The Optimum Plastics Extrusion Process

- The plastic extrusion process starts when polymer compounds and additives in the form of flakes, pellets, granules, or powders are constantly fed into the extruder through a hopper.

- When the material enters the barrel, it is heated in three or more heat zones. The screw gradually pushes these materials around the barrel, generating enough heat to melt the plastic composites.

- Because the screw and pressure generate heat, the heat zones do not need to be as hot as the needed extrusion temperature. External heaters aid in maintaining the proper temperature while the molten plastic flows through the barrel.

- When the material is driven through the die, it takes on the shape of the die opening, completing the extrusion process. Once the extrusion profile has passed completely through the die, it is cooled in a water bath or with a series of cooling rolls, causing it to solidify.

Conclusion:

It's also worth noting that hiring the correct firm to make plastic extruded parts or components broadens the possibilities that this fabrication technique offers.